- Special Applications

- Impregnation techniques, Partial discharge

- Avionics

Impregnation of winding materials

The material properties of produced transformers, coils, chokes, inductors or ferrites can be improved using impregnation. At STEGER we distinguish two general techniques, the standard impregnation and a special high-class impregnation.

With the standard impregnation the products gain an additional mechanical strength for long-term durability. The heat dissipation, as well as the corrosion protection, is improved. Additional benefits include vibration protection and improved noise performance. Excellent quality properties are achieved by a high degree of automation, cutting down the costs for our customers.

With a special high-class impregnation developed by STEGER a complete penetration of the windings and insulation up to the bobbin base is possible - even and particularly for complex winding structure. Combined with the specific design of the winding, the absence of partial discharge of the windings and insulation results from the special impregnation. Therefore, very high operating voltages on a very small space are possible. Products that undergo this procedure are extremely durable and can withstand high thermal cycling.

|

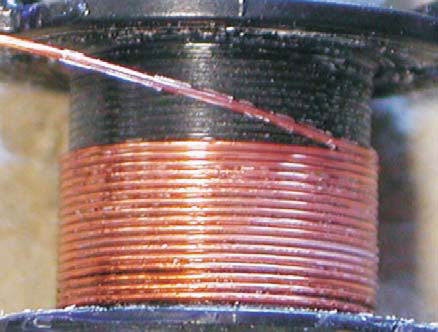

Sample from production. |

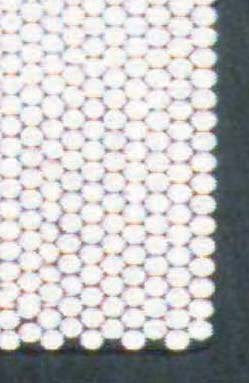

If required, the complete penetration until the bobbin base can be achieved by a special STEGER high-class impregnation - even for complex winding structures |

The cross-section shows the excellent winding process for this article. Sample from production. |